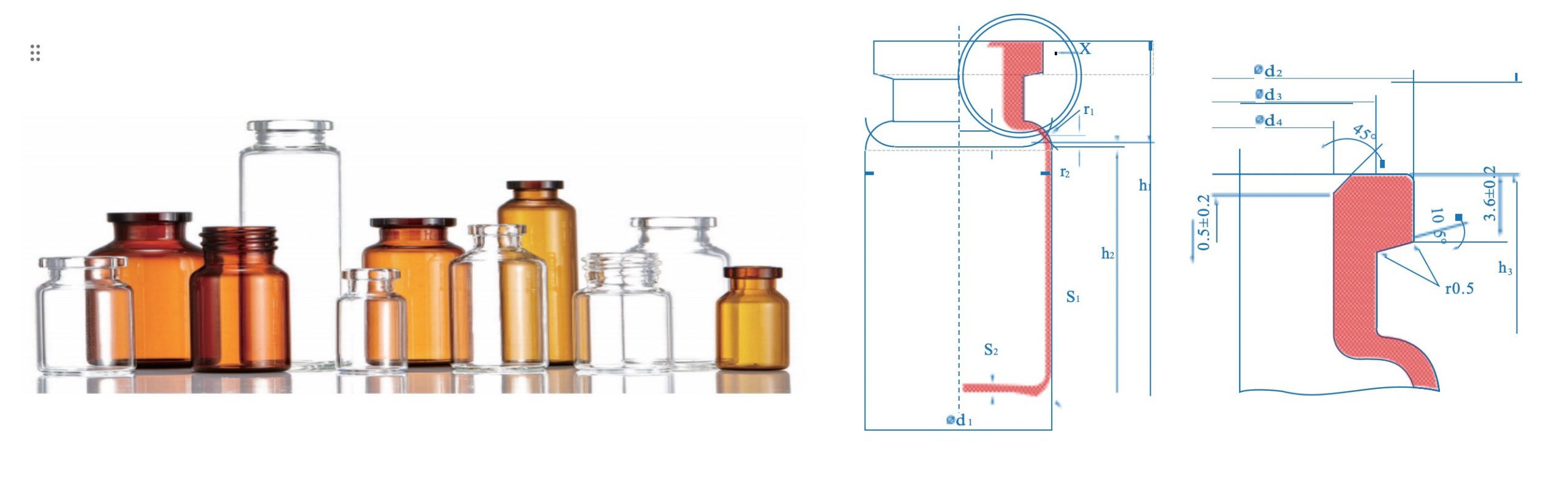

What Are Tubular Vials?

Tubular vials are specialized glass containers engineered for the safe and effective storage of various substances, ranging from pharmaceuticals to laboratory samples. Their design allows for consistent wall thickness and reduced risk of breakage, ensuring that sensitive materials are kept secure. The nature of these vials makes them ideal for applications requiring high strength and chemical resistance, particularly in the pharmaceutical sector where integrity is critical. Using tubular vials minimizes contamination risks while providing a reliable way to store drugs and vaccines. Their popularity is growing, especially in regions like Southeast Asia, where pharmaceutical manufacturing is on the rise, demanding high-quality packaging solutions.

The Role of Glass Injection Vials

Among the various types of packaging available, glass injection vials are particularly significant in the delivery of injectable medications. These vials are crafted from high-quality borosilicate glass, which provides excellent thermal stability and resistance to chemicals. For example, in the context of administering vaccines, using glass injection vials can enhance the preservation of active ingredients, ensuring that they remain effective throughout their shelf life. Additionally, healthcare providers appreciate that glass vials minimize the risk of leaching substances, a critical concern when it comes to patient safety. This makes glass injection vials a preferred choice in hospitals and clinics around the Philippines, especially in light of increasing demands for reliable medical supplies.

The Importance of Quality in Pharmaceutical Glass Vials Manufacturers

Choosing the right supplier is vital for ensuring that pharmaceutical glass vials manufacturers meet the stringent quality standards required in the healthcare industry. Quality assurance ensures that vials are free from defects and contamination, which can compromise the safety and efficacy of the medications stored within. Manufacturers who adhere to international standards create a competitive edge, which is crucial as the local pharmaceutical market continues to expand. For instance, manufacturers in the Philippines are increasingly integrating technologies that ensure precise manufacturing processes and enhance product purity. This proactive approach not only benefits manufacturers by streamlining their operations but also ensures that healthcare providers receive the best possible products for patient care. A reliable manufacturer will offer comprehensive support, addressing both logistical needs and product quality issues effectively.

Conclusion: Choosing the Right Manufacturer

In exploring the realm of tubular vials, glass injection vials, and the pivotal role of reliable pharmaceutical glass vials manufacturers, it becomes clear that quality matters. Readers should consider the advantages offered by companies like Linuo, which stands out for its commitment to excellence in the production of glass vials. With a solid reputation for supply reliability and adherence to international standards, Linuo emerges as a leading choice in the industry. Their focus on innovation and quality control translates to a superior product that effectively meets the needs of modern healthcare providers.